When it comes to acquiring heavy equipment for your business—whether you're in construction, agriculture, landscaping, or industrial services—budget and operational efficiency are top priorities. One of the most common dilemmas buyers face is choosing between new and used equipment.

While new machines come with the latest features and warranties, used equipment offers affordability and proven performance. So, how do you make the right choice?

In this article, we break down the cost-benefit dynamics of buying new vs. used equipment to help you make the most practical and profitable decision for your needs.

Initial Cost Comparison

One of the most obvious benefits of used equipment is its lower upfront cost.

- New Equipment: Generally priced at 100% of MSRP.

- Used Equipment: Can cost 30%–50% less, depending on age, condition, and hours of use.

Why it matters:

- Buying used equipment can free up capital for other investments (tools, staffing, technology).

- Lower monthly payments if financed.

- Reduced risk in tight-budget or one-time-use scenarios.

Depreciation and Resale Value

New equipment begins to depreciate the moment it leaves the dealer's lot—similar to a new car.

- A new machine can lose 15%–25% of its value in the first year.

- Used equipment has already passed through the steepest part of the depreciation curve.

Benefit of Buying Used:

- Better resale retention if you plan to upgrade or resell within a few years.

- More predictable long-term value based on equipment age and condition.

Warranty, Reliability & Repair Risk

New Equipment Pros

- Comes with a manufacturer warranty (1–3 years or more).

- Fewer mechanical surprises.

- Includes modern features (telematics, safety, fuel efficiency).

Used Equipment Considerations

- May not include warranty (unless dealer offers certified pre-owned programs).

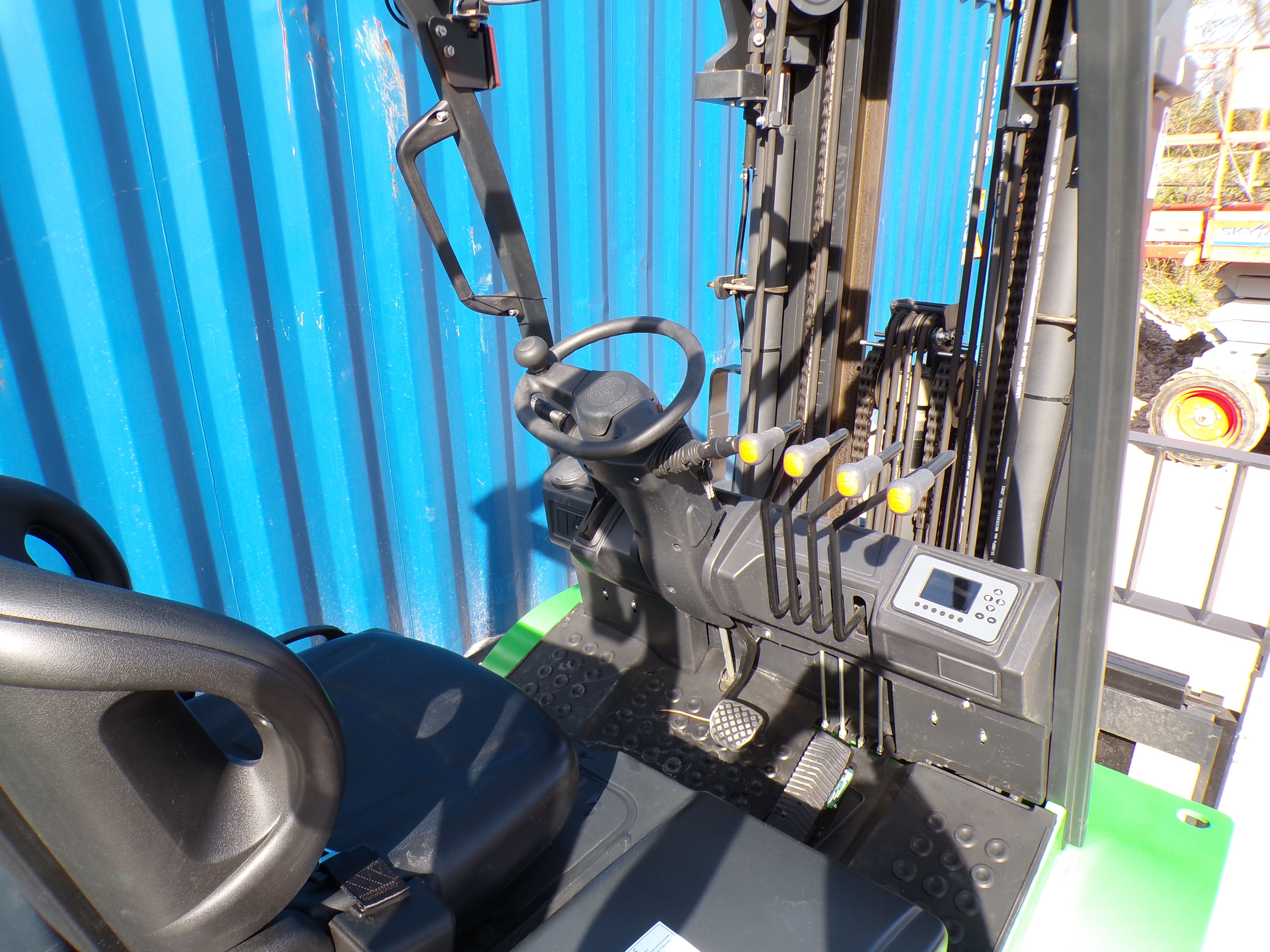

- Higher likelihood of wear on components (e.g., hydraulics, tracks).

- Inspection is critical—ask for service records, usage logs, and parts history.

Tip: Texas Equipment Source offers well-maintained, quality-checked used equipment, which minimizes your risk while saving you money.

Operational Performance

Your workload and usage frequency should heavily influence your choice.

Fuel Efficiency & Technology

Newer machines tend to be:

- More fuel-efficient

- Equipped with telemetry and diagnostics

- Compliant with latest emission standards

Used equipment may lack these benefits, but the tradeoff may be acceptable if the job doesn’t demand cutting-edge performance.

Tax Write-Offs and Incentives

Both new and used equipment may qualify for Section 179 deduction, which allows businesses to deduct the full purchase price of qualifying equipment purchased or financed during the tax year.

- Used equipment can also be depreciated over time, depending on tax structure.

- Always consult a tax professional to maximize your deductions.

Decision Matrix: When to Buy New vs. Used

Final Thoughts

There’s no universal answer to the “new vs. used” debate. The best decision depends on your budget, workload, and long-term strategy.

New equipment brings peace of mind, modern features, and long-term performance—ideal for companies scaling up. On the other hand, used equipment delivers significant cost savings and is perfect for temporary jobs, startups, or supplemental use.